Features

Cutting-edge cellulose

Date: 2019-12-13 16:51:36.0

Author: Jon Evans

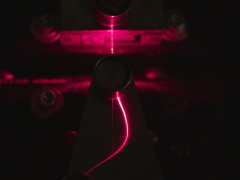

The cellulose optical fiber developed by VTT.

Photo: VTT.

Despite being one of mankind’s oldest materials, wood is still keeping up to date with the latest technologies, even if mainly via its cellulose. After being used to make a loudspeaker (see Wood: looking good and sounding good) and a water-purification filter (see Cellulose adapts to new roles), cellulose from wood has recently shown potential for producing flexible electrodes for batteries and supercapacitors, and even optical fibers.

Batteries are already an essential part of our modern lives, powering almost all our portable electronic devices, from smartphones to hedge cutters. And with the rise of electronic vehicles and the growing need to store the energy produced by intermittent renewable sources such as solar and wind, batteries are only going to become even more essential. But these new applications will place ever greater demands on batteries, in terms of cost and storage capacity, requiring scientists to develop new battery technologies and improve existing ones.

One approach is to produce better battery electrodes, able to store more charge over shorter periods of time, by taking advantage of conductive two-dimensional (2D) materials such as graphene. Because these 2D materials are just a few atoms thick at most, they offer a large surface area for storing charged particles.

Their downside is that the electrodes they produce are fairly fragile and brittle. Recently, however, a team of scientists from Sweden and the US, led by Max Hamedi at KTH Royal Institute of Technology in Stockholm, has developed more robust versions by combining the 2D material with cellulose nanofibrils.

Specifically, they combined a 2D material called MXene, made up of a layer of titanium atoms and a layer of carbon atoms, with cellulose nanofibrils derived from softwood, which were just 3.5nm wide but tens of micrometers in length. They did this by simply mixing the two materials in water, finding that not only did functional groups on the surface of the titanium layer naturally bind with the cellulose nanofibers, but the MXene also seemed to get tangled up in the long nanofibrils.

As the scientists report in a paper in Advanced Materials, this meant that while the resulting composite was highly conductive, it was also very robust, with a mechanical strength of 340MPa, compared with just 29MPa for pure MXene sheets. The composite was also flexible, meaning it could potentially find use in wearable electronics, and could even be printed into various shapes.

While wood is naturally known for its strength, it’s not known for its transparency, but nevertheless Ali Harlin and his colleagues at the VTT Technical Research Centre of Finland have found a way to create an optical fiber from softwood-derived cellulose. An optical fiber consists of a material with a high refractive index surrounded by a material with a lower refractive index, meaning these materials deflect light passing through them to different extents. This set up induces a state of total internal reflection, so that a beam of light introduced into the fiber is always reflected away from the interface between the two materials. The beam thus becomes trapped within the fiber and forced to travel along it.

In a conventional optical fiber, glass is surrounded by plastic, but Harlin and his team wondered whether they could make both materials from cellulose. For the high refractive index material, they dissolved the cellulose in an ionic liquid and used a technique called dry-jet wet spinning to pull out a fiber from the solution. Then they coated this fiber in cellulose acetate, a polymer that has been produced for over 100 years.

As Harlin and his colleagues report in a paper in Cellulose, although both the cellulose fiber and the cellulose acetate were transparent, the fiber had a higher refractive index, which duly allowed it to transmit visible light just like a conventional optical fiber. It didn’t do this as efficiently as a conventional optical fiber, though, which means it couldn’t at the moment be used for communications applications. But it could be ideal for sensing applications, because Harlin and his colleagues showed that the transmission of light through the fiber was altered when it interacted with compounds such as water.

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 2 keywords used to tag this article:

- Jules Audemars-Australia Best Quali

- DG6582 Mens Moncler Down Jackets Gr