Features

Better together

Date: 2020-07-10 10:36:20.0

Author: Jon Evans

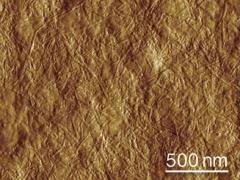

Conductive film of MXene and cellulose made

by Hamedi's team.

For a material that was discovered by accident, MXenes have more than proven their worth over the past 10 years. This is because they possess a range of highly useful properties, including electrical conductivity, water solubility and the ability to absorb electromagnetic radiation, that has seen them utilized for everything from conductive inks to energy storage to water desalination. What is more, researchers have found that they are perfectly amenable to being combined with other materials, offering a way to enhance their properties still further. And one of those other materials is cellulose.

MXenes are two-dimensional (2D) materials, meaning materials made up of a single layer of atoms or molecules. The most famous 2D material, graphene, is made up of a single layer of carbon atoms, whereas MXenes comprise up to three layers of carbon or nitrogen atoms sandwiched between layers of a transition metal such titanium or chromium to form a single molecular layer.

The best known, and most studied, MXene comprises two layers of carbon atoms sandwiched between three layers of titanium atoms (Ti3C2), which is the most conductive MXene produced to date. MXenes are also covered in oxygen, hydroxide and fluoride groups, known as surface terminations, as a consequence of the etching process that produces them from a parent ceramic compound; these surface terminations are what make them soluble in water.

This means that, unlike graphene, MXenes can be processed in water, and thus readily turned into conductive inks or combined to produce conductive films. Unfortunately, these films aren’t very strong or flexible, which is why a team of scientists from Sweden and the US, led by Mahiar Hamedi at the KTH Royal Institute of Technology in Stockholm, decided to try strengthening them by adding cellulose nanofibers.

Because both MXene and cellulose nanofibers are soluble in water, Hamedi and his team could easily join them together by just mixing two solutions. On drying this mixture, they found that the nanofibers and MXenes naturally formed strong interactions with each other, in part thanks to the surface terminations on the MXene. In addition, the flat MXene flakes essentially became tangled up in the long cellulose nanofibers.

As Hamedi and his colleagues reported last year in a paper in Advanced Materials, the end result was a conductive film with a strength more than 10 times greater than pure MXene film, at 341 megapascals (MPa). They also showed that their mixture of MXene and cellulose nanofibers could make an effective conductive ink, allowing them to print a robust, flexible supercapacitor for storing electrical charge.

But now a team of scientists from Switzerland and Singapore, led by Gustav Nyström at the Swiss Federal Laboratories for Materials Science and Technology (Empa), has shown that it’s not just the strength of MXene that can be enhanced by adding cellulose nanofibers. Nyström and his colleagues were looking to take advantage of MXene’s ability for absorbing electromagnetic radiation to develop a novel electromagnetic interference (EMI) shielding material.

Such shielding is required to protect sensitive electrical components from the damaging effects of electromagnetic radiation and has traditionally been achieved with thin metal sheets. As electrical components get smaller and smaller, however, effective shielding materials need to become lighter and thinner.

MXene has already shown its ability as a nanoscale shielding material, with a film comprising 24 layers of MXene, just 55nm thick, able to produce 99% shielding. But Nyström and his colleagues wondered whether a combination of MXene and cellulose might prove even better, by allowing the creation of a robust, lightweight aerogel with pores that can also trap electromagnetic radiation.

To produce their aerogel, Nyström and his colleagues again mixed solutions of MXene and cellulose nanofibers, poured this mixture into a mold and then slowly froze it. As they report in a paper in Advanced Science, this produced a porous aerogel in which MXene ‘bricks’ are bonded by cellulose nanofiber ‘mortars’, which turned out to be the lightest electromagnetic shielding material ever developed.

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 2 keywords used to tag this article:

- Jules Audemars-Australia Best Quali

- DG6582 Mens Moncler Down Jackets Gr