Features

Artificial biofilm natural for MFCs

Date: 2017-04-20 11:30:45.0

Author: Jon Evans

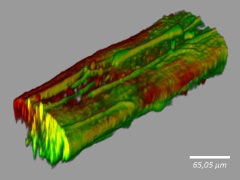

A confocal microscope image of PVA

threads coated with S. oneidensis bacteria

(green: living bacteria; red: dead bacteria).

Image: Patrick Kaiser.

In theory, microbial fuel cells (MFCs) offer a highly efficient way to convert organic material, including waste materials, into electricity. Bacteria in an anode chamber break down the organic material to release electrons and hydrogen ions (protons) that travel to a cathode chamber where they combine with oxygen to produce water. The protons pass through a cation-exchange membrane separating the anode and cathode chambers, while the electrons are taken up by a metal anode and then travel round an external circuit, generating electricity.

In practice, however, this efficiency has proved difficult to achieve. For a start, only a few species of bacteria, termed bioelectrogenic, are able to utilize a metal anode as an electron acceptor, and then only under anaerobic conditions when oxygen isn’t available to perform that role. Many MFCs developed to date have used solutions of free bacteria in the anode chamber. But that makes it difficult to supply organic material continuously, which would be the most efficient way of operating, because this would flush out the bacteria, requiring regular and expensive top-ups.

One potential solution is to encourage the bacteria to form biofilms on the anode. Biofilms comprise bacterial cells embedded in a sticky extracellular polymeric substance made up of DNA, proteins and polysaccharides, and thus provide a way to stick bacteria in place, preventing them from being washed away. Once again, however, this solution works better in theory than in practice.

Biofilms are most effectively produced by communities of microbes rather than a single species, but MFCs only employ single species of bioelectrogenic bacteria and try to avoid contamination with non-bioelectrogenic species. What is more, biofilms take a long time to form and are unstable. So Ruth Freitag and her colleagues at the University of Bayreuth in Germany decided to try producing their own artificial biofilm for use with MFCs.

The approach they took involved electrospinning a solution of the bioelectrogenic bacterium Shewanella oneidensis and polyvinyl alcohol (PVA). Electrospinning uses an electric force to draw charged threads out of a polymer solution; in this case, the process produced bacteria-covered polymer threads around 450nm in diameter, which the researchers deposited onto a copper mesh. Finally, they coated the threads with poly(p-xylylene) (PPX) to stabilize the PVA, which would otherwise dissolve when exposed to an aqueous solution, and to prevent contamination.

Although electrospinning is known to be a fairly gentle process, Freitag and her colleagues first tested whether it and the PPX treatment harmed the bacteria in any way. Using a staining technique that could distinguish between living and dead cells, they discovered areas of dead cells scattered over the newly formed and treated threads. After seven days, however, these areas had mainly been colonized by living cells, showing that the electrospinning and treatment processes had no long-term detrimental effects on the bacteria.

Next, they produced an MFC by combining the thread-covered copper mesh, acting as the anode, with a cation-exchange membrane and a graphite cathode. As they report in Macromolecular Bioscience, on exposing the anode to a solution of lactic acid, they found their MFC could achieve a power density of around 65mW/m2. This is twice as high as could be achieved with an MFC employing a natural S. oneidensis biofilm, which was formed on a graphite anode under aerobic conditions and then transferred to the MFC. Natural biofilms were also far less stable, only operating properly in around 30% of the experiments.

The power density of the artificial biofilm was, admittedly, only around half that of a solution of free S. oneidensis, but the artificial biofilm has the advantage that it can be continuously supplied with organic material. Also, the PPX coating ensures that, unlike conventional MFCs, this MFC can be operated under non-sterile conditions. Finally, electrospinning is already a widely-used industrial technique, which means there shouldn’t be much problem producing these artificial biofilms on an industrial scale in practice.

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 10 keywords used to tag this article:

- Top quality swiss replica Couple wa

- Mont Blanc Marlene Dietrich Special

- datejust 36

- Rolex

- Nuove cuffie Arrivo | Beats By Dre

- Replica Rolex Datejust Special Edit

- Rado Watches : Replica Watches Fact

- Replica Richard Mille watches

- IWC Fliegeruhr : Diseñador Swiss R

- CLFJ145 925 Sterling Silver Hug Pan