Features

Just like buses

Date: 2017-06-29 12:53:31.0

Author: Jon Evans

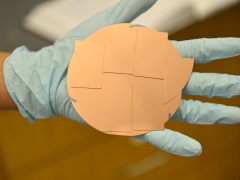

The copper catalyst developed by scientists

at Stanford University.

Photo: Mark Shwartz/Stanford University.

In addition to its many other uses, copper is able to catalyze electrochemical reactions between carbon dioxide and water to produce a range of hydrocarbons, including ethanol. Unfortunately, it’s not actually very good at doing this, tending to produce a wide range of different hydrocarbons at low yields and too much hydrogen. Now, though, in two recent papers in the Proceedings of the National Academy of Sciences, scientists report discovering two different, but potentially complementary, ways to improve its performance.

In the first study, a team of scientists from the Lawrence Berkeley National Laboratory (LBNL) and the California Institute of Technology in the US, led by Ethan Crumlin at LBNL, studied the catalytic reaction with a technique called X-ray photoelectron spectroscopy. They then interpreted their experimental findings using quantum mechanics theories.

This revealed that a layer of oxygen atoms just below the surface of the copper catalyst was essential for promoting the reaction between carbon dioxide and water. The subsurface oxygen appears to play a critical role in binding the carbon dioxide to the surface of the copper at room temperatures and in orientating the carbon dioxide molecules in such a way that they can readily react with water molecules.

"The modest amount of subsurface oxygen helps to generate a mixture of metallic and charged copper that can facilitate the interaction with carbon dioxide and promote further reactions when in the presence of water," explained Crumlin.

Oxygen could be just the start, though, because the researchers think that incorporating other atoms, such as sulfur or chlorine, just below the surface may offer a way to influence what specific hydrocarbons are produced by the copper catalyst. Such control over the reaction has not previously been possible.

In order to reduce the number of factors that might influence the catalytic reaction, Crumblin and his team studied copper foil with a single crystal structure, which they produced from a polycrystalline sample by repeated argon sputtering and annealing. This implies that copper surfaces with different crystal structures might differ in their catalytic ability, which is what a team of US scientists led by Christopher Hahn and Thomas Jaramillo at Stanford University decided to explore in their study.

Crystal structure refers to the regular arrangement of atoms or molecules in a crystalline material like a metal. Each specific arrangement can be designated by a three-figure index known as the Miller index; Crumblin and his team studied copper (111), for example. Most natural crystalline materials are polycrystalline, comprising a variety of different arrangements, and so the first challenge for Jaramillo and his colleagues was to produce copper surfaces with specific crystal structures.

Unfortunately, current techniques for producing specific crystal structures from polycrystalline materials, like argon sputtering, can only create fairly small samples, around 1mm2. "With such a small crystal, it's hard to identify and quantify the molecules that are produced on the surface," said Hahn. "This leads to difficulties in understanding the chemical reactions, so our goal was to make larger copper electrodes with the surface quality of a single crystal."

To do this, the scientists developed a method for growing a layer of copper on top of a wafer of silicon or sapphire with a specific crystal structure, which was then transferred to the copper layer. In this way, they were able to produce copper layers with three distinct crystal structures – 100, 111 and 751 – and then compare their catalytic abilities.

This revealed that although all three surfaces were catalytic, copper (751) was better at producing useful hydrocarbons such as ethanol and propanol. "An atom of copper (751) only has two nearest neighbors," explained Hahn. "But an atom that isn't bonded to other atoms is quite unhappy, and that makes it want to bind stronger to incoming reactants like carbon dioxide. We believe this is one of the key factors that lead to better selectivity to higher-value products, like ethanol and propanol."

Until recently, scientists had no way to control the efficiency or selectivity of copper catalysts, now they have two.

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 8 keywords used to tag this article:

- Copy Omega Constellation watches 11

- Pandora White Faceted Murano Charm

- Replica Rolex Air-King Watch Oyster

- Replica Watches Monza Calibre 36

- Часы Реплика Breguet

- Connection Problem

- Omega 123.50.38.21.52.001 Men - Con

- Copy Watches ROLEX DATEJUST 116231A