Features

Through the membrane

Date: 2018-05-16 09:49:33.0

Author: Jon Evans

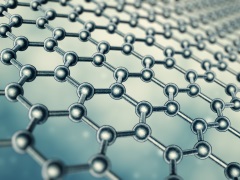

Graphene.

The fact that the production of cellulosic ethanol requires lots of different steps – pre-treating the biomass, converting the cellulose to fermentable sugars, fermentation and extracting the ethanol – has helped to ensure that it struggles to compete competitively with fossil fuels. The one advantage of having lots of different steps, however, is that it provides lots of scope for making the production process more economical, by improving the efficiency of each step. Indeed, small improvements in each step can lead to large improvements in the efficiency of the production process as a whole.

The focus of such improvement efforts has tended to be on the front end of the production process, particularly the pre-treatment and cellulose conversion steps, but researchers are also looking at the back end. In particular, they’re looking for more efficient ways to dehydrate the bioethanol.

As the yeast that conduct the fermentation step are suspended in a liquid medium in a bioreactor, the ethanol they produce is mixed with water, which need to be separated from each other. Traditionally, this has been done by distillation, but that requires a lot of energy. More recently, biofuel producers have employed molecular sieves, in the form of tiny water-absorbing beads, to separate the ethanol and water.

An alternative option beginning to come to the fore is membrane-based processes. Both polymer membranes and zeolite membranes have shown much potential for separating ethanol and water, with Mitsubishi Chemical recently launching a range of zeolite membranes called ZEBREX for bioethanol production. But recent advances in material science are also leading researchers to investigate the potential of other types of membranes for dehydrating ethanol.

One of these is known as polymers of intrinsic microporosity (PIMs). Whereas the pores in conventional semi-permeable polymer membranes are produced by chemical or physical treatments, the polymer strands in PIMs are designed so they can’t pack tightly together, producing inherent micropores. PIMs have already shown great potential for separating gases, and so a team of Chinese scientists led by Jianwen Jiang at the National University of Singapore wondered whether they would prove equally effective at separating ethanol and water.

To find out, they developed a computer simulation of a type of PIM known as PIM-1. As they report in a paper in the Journal of Membrane Science, this simulation revealed that PIM-1 should be able separate water and ethanol faster and more effectively than conventional semi-permeable membranes made from poly(vinyl alcohol) and polybenzimidazole.

Another novel material being explored for its separation abilities is graphene, an atomic-thick sheet of carbon atoms arranged like chicken wire (see image). Rather handily, a form of graphene covered in various oxide groups, known as graphene oxide, spontaneously comes together to form a porous membrane when dispersed in water, although other chemicals also need to be added to stabilize the membrane. Now, Wanqin Jin and his colleagues at Nanjing Tech University in China have found a way to stabilize graphene oxide membranes so they can efficiently separate water and ethanol.

This involves adding calcium lignosulfonate, which in solution separates into calcium cations and lignosulfonate anions. As the researchers report in a paper in ChemSusChem, both the anions and cations bind to the oxide groups on graphene oxide, producing membranes stable enough to separate water and ethanol. To try to improve the separation performance of these membranes, Jin and his colleagues added a layer of polyethylenimine (PEI) to prevent the formation of defects and inserted titanium dioxide nanoparticles to increase the size of the nanochannels running through the membrane and thus improve the flow of water.

In tests, they found that a membrane made up of 15 bilayers of graphene oxide and PEI with nanoparticles could separate water and ethanol at a flow rate of 4000g/m2/hour, producing water that was over 98% pure. This is better than any other advanced polymer- or graphene-based membranes. They also found that the membrane doesn’t work because it physically blocks the ethanol, which is small enough to pass through the nanochannels, but rather because water has a much stronger affinity for the membrane than ethanol.

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 1 keywords used to tag this article:

- Datejust