Features

Reducing the burden of carbon dioxide

Date: 2018-09-28 11:02:50.0

Author: Jon Evans

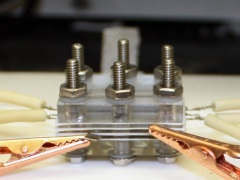

The flow electrolyser developed by Feng Jiao

and his colleagues.

Photo: Feng Jiao.

Reacting carbon dioxide with water over a copper-based catalyst offers both a quick and easy way to produce useful hydrocarbons such as acetate and ethanol and an effective way to limit carbon dioxide emissions to the atmosphere. But although potentially quick, easy and effective, this process isn’t currently very efficient, requiring lots of electricity to power it and tending to produce a wide range of different hydrocarbons at low yields.

Given its undoubted promise, however, scientists have been working hard to understand the process in the hope of improving it (see Just like buses). Now, Feng Jiao and his colleagues at the University of Delaware in the US have developed a version of the process able to produce a greater proportion of useful hydrocarbons than ever before.

For carbon dioxide to react with water, the carbon dioxide first needs to be reduced to carbon monoxide, which is much more reactive. Normally, the carbon dioxide reduction and carbon monoxide reaction is performed in a single step, but Jiao and his colleagues decided to separate them and then focus on the reaction, as previous studies had shown that this approach can aid the production of useful hydrocarbons. They also decided to replace the water with an aqueous solution of potassium hydroxide, as alkaline conditions can also aid the production of useful hydrocarbons.

As Jiao and his colleagues report in a paper in Nature Chemistry, their version is conducted in a flow electrolyser containing a flat cathode made of copper particles on a porous carbon support. The copper in the particles is known as oxide-derived copper, because it is produced by reducing particles of copper oxide. This cathode is separated from a flat anode made of iridium oxide by an ion-exchange membrane; the cathode, anode and membrane are arranged with spaces between them, forming several parallel compartments.

The idea is to flow carbon monoxide over the cathode, while also flowing potassium hydroxide in the compartments formed between the cathode, membrane and anode. This setup ensures that the carbon monoxide and potassium hydroxide are flowing on opposite sides of the cathode. As they flow by, the carbon monoxide and potassium hydroxide can both enter the pores of the cathode, allowing them to come into contact and react, catalyzed by the copper particles. Any gaseous products are carried away by the flow of carbon dioxide, while any liquid products are carried away by the flow of potassium hydroxide.

When Jiao and his colleagues tested their electrolyser, they found that over 90% of the products generated by the reaction between carbon monoxide and potassium hydroxide were useful multi-carbon compounds such as ethylene, propanol, acetate and ethanol. This compares with yields of multi-carbon compounds of around 55% for previous systems. Further investigations revealed that the secret to the electrolyser’s efficiency appeared to be the formation of a stable triple-phase boundary between the carbon monoxide, potassium hydroxide and copper particles.

Nevertheless, much more needs to be done before Jiao and his colleagues can think about commercialization. This includes making the fuel cell more energy efficient, even though the idea is to power it with renewable sources of energy such as solar that don’t generate any additional carbon dioxide. They also need to prevent the pores in the cathode from becoming blocked and find an efficient method for reducing carbon dioxide to carbon monoxide.

Jiao and his colleagues are currently working on many of these issues with scientists at Tianjin University in China, with the eventual aim of developing a prototype reactor. They recently received a $500,000 grant from the US National Science Foundation to help support these efforts.

"We hope this work will bring more attention to this promising technology for further research and development," Jiao said. "There are many technical challenges still be solved, but we are working on them!"

The views represented here are solely those of the author and do not necessarily represent those of John Wiley and Sons, Ltd. or of the SCI.

Displaying 2 keywords used to tag this article:

- Jules Audemars-Australia Best Quali

- DG6582 Mens Moncler Down Jackets Gr